Product List

SyrupOral Liquid Production Line

Description

This syrup and oral liquid production line made up of CLQ ultrasonic washing, RSM drying &sterilizing machine, DGZ filling & capping machine, which can complete following functions of ultrasonic washing ,flushing, (air charging, drying& sterilizing), filling and capping /screwing.

Liquid manufacturing plant is suitable for oral liquid and other other small dose solution , and with a labeling machine consisting an ideal production line.

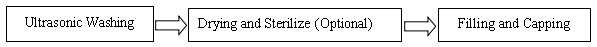

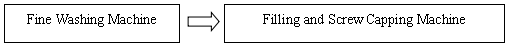

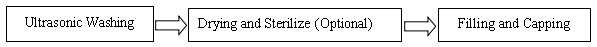

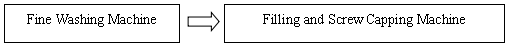

Flow Chart

Oral liquid:

Syrup liquid:

Parameters of Syrup and Oral Liquid Production Line

Characteristics

1. Liquid manufacturing plant adopts advanced ultrasonic washing, alternating washing with independent multiple nozzle washing with water, air separately and quartz tube ultraviolet hot radiation sterilizing with high temperature, advanced technology of multiple nozzle filling and sealing .

2. Syrup and oral liquid production line is equipped with compact structure, featuring small occupying area.

3. Control system adopts photoelectric technology and PLC with color touch LCD screen, high automation, few operator.

4. Integrate machine (SQGF ) one machine can wash, fill and screw bottle in one machine, reduce investment and production cost.

5. Universal parts, few specification parts, easy to exchange.

This syrup and oral liquid production line made up of CLQ ultrasonic washing, RSM drying &sterilizing machine, DGZ filling & capping machine, which can complete following functions of ultrasonic washing ,flushing, (air charging, drying& sterilizing), filling and capping /screwing.

Liquid manufacturing plant is suitable for oral liquid and other other small dose solution , and with a labeling machine consisting an ideal production line.

Flow Chart

Oral liquid:

Syrup liquid:

Parameters of Syrup and Oral Liquid Production Line

| Model | Production line | Suitable size | Production capacity | Power | Overall dimension |

| BXKF5/25 | CLQ60 | 5 to 25ml | 18000pcs/h | 45kW | 9000×2000×2100(mm) |

| RSM480/18 | |||||

| DGZ12 | |||||

| SQGF 18/6 | SQGF 18/6 | 50 to 500ml | 7200pcs/h | 3.2kW | 4800×2038×2400(mm) |

| XGJ50/8 | LQJ50 | 50 to 250ml | 6000pcs/h | 9.5kW | 5500×2200×2100(mm) |

| GXJ8/8 |

Characteristics

1. Liquid manufacturing plant adopts advanced ultrasonic washing, alternating washing with independent multiple nozzle washing with water, air separately and quartz tube ultraviolet hot radiation sterilizing with high temperature, advanced technology of multiple nozzle filling and sealing .

2. Syrup and oral liquid production line is equipped with compact structure, featuring small occupying area.

3. Control system adopts photoelectric technology and PLC with color touch LCD screen, high automation, few operator.

4. Integrate machine (SQGF ) one machine can wash, fill and screw bottle in one machine, reduce investment and production cost.

5. Universal parts, few specification parts, easy to exchange.

Spanish

Spanish French

French Arabic

Arabic