Product List

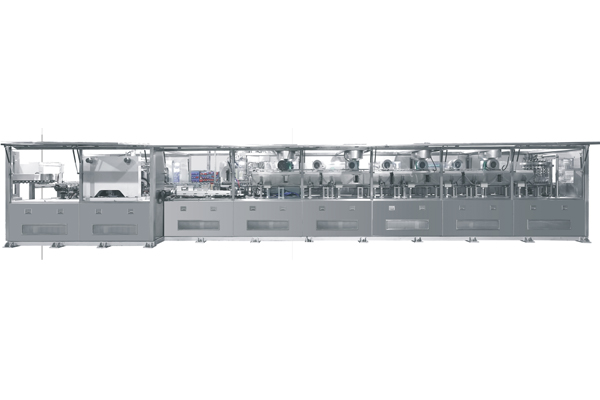

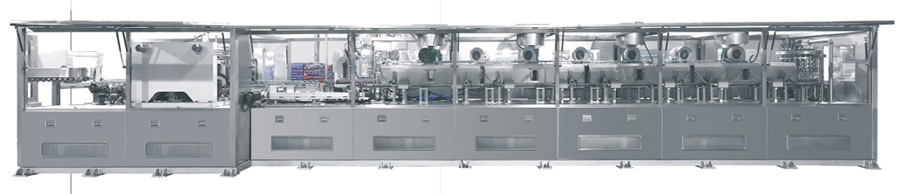

Linear PP Bottle Blowing Machine ( CPP Series)

Description

CPP series bottle blowing machine is used for high production automatically blowing of IV bottle and other PP bottles, includes stations of preform loading, preform heating, preform delivering, blowing, bottle taking out. The blown bottles are suitable for filling glucose infusion, sodium chloride infusion, glucose and sodium chloride injection, metronidazole injection, etc.

Features of Linear Blow Moulding Machine

1. Different performs loading, no need to change any spare parts

2. Fully servo electric control

3. Piston type high pressure mold lock, improving blown bottle quality

4 Stable power output, ensure bottle uniform thickness

5. Max production capacity 12000 bottles per hour

Technical Parameters of PP Bottle Blowing Machine

CPP series bottle blowing machine is used for high production automatically blowing of IV bottle and other PP bottles, includes stations of preform loading, preform heating, preform delivering, blowing, bottle taking out. The blown bottles are suitable for filling glucose infusion, sodium chloride infusion, glucose and sodium chloride injection, metronidazole injection, etc.

Features of Linear Blow Moulding Machine

1. Different performs loading, no need to change any spare parts

2. Fully servo electric control

3. Piston type high pressure mold lock, improving blown bottle quality

4 Stable power output, ensure bottle uniform thickness

5. Max production capacity 12000 bottles per hour

Technical Parameters of PP Bottle Blowing Machine

| Machine models | |||||||||||||

| Item | CPP4 | CPP6 | CPP8 | CPP10 | CPP12 | ||||||||

| Design capacity | 100-250ml | 4000 B/H | 6000 B/H | 8000 B/H | 10000 B/H | 12000 B/H | |||||||

| 500ml | 3000 B/H | 5000 B/H | 7000 B/H | 9000 B/H | 10000 B/H | ||||||||

| Preform material | PP | ||||||||||||

| Mould cavity no. | 4 | 6 | 8 | 10 | 12 | ||||||||

| Compressed Air | Low pressure | 8-10Bar 3m3/min | 8-10Bar 4m3/min | 8-10Bar 5m3/min | 8-10Bar 6m3/min | 8-10Bar 7m3/min | |||||||

| High pressure | 20-25Bar 6m3/min | 20-25Bar 8m3/min | 20-25Bar 10m3/min | 20-25Bar 12m3/min | 20-25Bar 15m3/min | ||||||||

| Cooling water | Heating part | 20-30℃, 5-7m³/h | |||||||||||

| Mould part | 10-15℃, 2-4m³/h | ||||||||||||

| Power supply | 380V, 50Hz, 3 phase 4 wire | ||||||||||||

| Heating power | 160kW | 164kW | 175kW | 187kW | 192kW | ||||||||

| Installed power | 234kW | 250kW | 258kW | 263kW | 270kW | ||||||||

| Machine weight | 13T | 13.2T | 13.8T | 14.2T | 14.5T | ||||||||

| Overall Dimension(m) | Main set (L×W×H) | 11.38 × 1.71 × 2.2 | 11.68 × 1.71 × 2.2 | 11.98 × 1.71 × 2.2 | 13.25 × 1.71 × 2.2 | 13.75 × 2.15 × 2.2 | |||||||

Spanish

Spanish French

French Arabic

Arabic